|

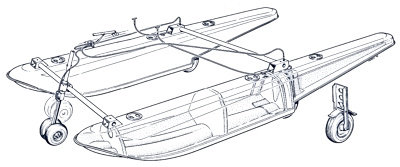

Three very different float designs are available for the Challenger: composite, aluminum and inflatable. All have straight and amphibious configurations. For over 20 years the vast majority of Challenger owners have chosen composite amphibious floats made by Puddlejumper Floats of Canada. Composites allow for a strong yet light, sleek and slippery, structure with no rivets or seams. Compared to the aluminum and inflatable amphibious floats, Puddlejumpers are lighter (so you can carry more payload), they are more hydrodynamic (so you can lift the payload out of the water sooner), and they are more aerodynamic (so you can carry the payload faster). Puddlejumper amphibs only add 100 lbs to your empty weight and they only subtract 10 mph from your cruise speed. This is a fraction of the impact of aluminum and inflatable amphibs. Puddlejumper amphibs are also thousands of dollars cheaper! The numbers speak for themselves! Puddlejumper floats were designed from the outset for amphib operations. Unlike all other floats on all other planes the Puddlejumper amphibious versions have negligible cost, weight and performance penalties compared to straight floats. The flexibility and convenience of choosing freely between water and land operations makes the Puddlejumper amphibs irresistible. The 14 foot Puddlejumpers have 1000 lbs of displacement per float which provides excellent buoyancy for the entire Challenger line of aircraft. Using the conservative requirements of the TC CAR 523.751 and FAA TSO-C27 regs for certified seaplanes this allows for gross weights of up to 1110 lbs while still providing 80% reserve buoyancy. This is more than sufficient for the new Challenger Light Sport XL-65 with its gross weight of 1060 lbs, the highest of all Challenger models. The unique Puddlejumper pontoons, unlike conventional float designs, are wide and shallow rather than narrow and tall. This means Challengers on Puddlejumpers can operate in water only inches deep! In light winds the Challenger can be maneuvered on the water with just the air rudder - the prop is so close that it doesn't take much power to steer. The optional water rudder allows operations in confined spaces and higher winds. The use of composites allows Puddlejumpers to utilize a unique tunnel hull design rather than the v-shaped hulls of aluminum floats or the flat bottoms of inflatables. Such sophisticated shapes are simply not feasible to render in aluminum or inflatable structures. Patterned after offshore racing powerboats the tunnel makes a concave channel which traps air in the centre of the float between the two planing edges. This entrapment of air creates aerodynamic lift in addition to the hydrodynamic lift from the hulls. Theoretical research and full-scale testing of tunnel hulls has demonstrated the dramatic contributions of 'close-proximity ground effect' on aerodynamic lift and drag in operation. The lift together with a minimum amount of hull surface in contact with the water enables much more rapid acceleration onto the step and then to liftoff speed and much easier breaking free from the water. Once airborne the hulls also create lift which helps to offset their weight in flight. Tunnel hulls break up the surface tension of glassy water - the "suction" effect which makes it hard for floats to get out of the water and airborne in smooth conditions without ripples or waves. This allows the Challenger with its large wing and high power-to-weight ratio to take off from glassy water in a fraction of the distance of other aircraft on aluminum floats and inflatable floats. Puddlejumper's offshore racing heritage means the floats also work extremely well in rough water. Bulky inflatable floats with flat bottoms flop around on top of rough water, bashing into one wave after another like whitewater rafts. The distribution of buoyancy favours the front of PJ floats so they ride well in rough water without burying the bows in the waves. Even taxiing in high winds on turns from downwind to upwind the bows tend not to submerge. The hulls of the Puddlejumper floats are constructed of fibreglass and each pontoon has three watertight compartments separated by bulkheads. Optionally the bottoms or the entire hulls can be manufactured in kevlar. There is also an option to have the gel coat coloured to match your paint scheme. All rigging hardware needed to attach the floats to Challengers is provided. A five point attachment system is used so when the seasons change you can switch your Challenger between floats and skis or wheels in only 90 minutes. Rigging hardware is all aircraft aluminum and stainless steel to obviate corrosion. An optional Salt Water Operations package is available with special salt water wheel bearings, stainless steel axles, and isolation bushings between the stainless steel axles and the aluminum forks. Puddlejumpers have an elegantly simple gear retraction and extension mechanism. Cables and gravity are used to avoid electric, air or hydraulic screw ups. Wheel locking is positive and mechanical rather than over centre or pressure based.

The main wheels retract into wells in the pontoons while the nosewheel goes up and down like an upside-down periscope. The steerable nosewheel gives easy maneuvering on land and permits operation in 20 mph crosswinds. The new third generation landing gear is extremely rugged having been designed for aircraft up to 1232 lbs. This is well in excess of even the highest grossing Challengers, for example the new Light Sport XL-65 with its max takeoff weight of 1060 lbs. Challengers on amphibious Puddlejumpers have plenty of ground clearance so they operate routinely from grass and dirt venues, not just the smooth pavement required for many amphibs. The third generation amphibs have reinforced hulls, 70% stronger nose gear, larger nose wheels and larger main wheel wells with 6" forks for larger wheels. Hydraulic disc brakes have replaced the drum brakes used in the past. There have been many other less obvious improvements including, for example, a stainless steel wear plate in the nose gear down lock. Puddlejumper floats cost thousands of dollars less than aluminum and inflatable floats, and many thousands of dollars less than other composite amphibious floats. Everything needed to install and operate PJ amphibs on Challengers comes with the package. You do not have to design and fabricate mounting structures and operating mechanisms nor determine where to place the plane on the floats and at what angle. Challengers with the 582 Power Pack on amphibious Puddlejumper floats outperform all other aircraft in the class. Our combination of light airframe and large wing requires much less horsepower than the alternatives. Click the picture above for videos! Other aircraft to come near the Challenger's payload and performance need a 100 hp Rotax 912 which is $25,000 for the engine alone! The mounts, prop, etc are another $5,000! And then there's the bigger, more expensive floats... We timed the water takeoff run of a competitor with a 912 and amphibious floats. The 582 Challenger takes off in half the time and at much less cost! Seaplane pilots say that float flying is the hard drugs of aviation - instantly addictive! To see why click here, here, here, here, here, here, here and here!!!

To learn and see more order our comprehensive information package and video! |